Ansys, a Pittsburgh-based engineering simulation company, recently partnered with Siemens Energy to improve the design process for creating additive manufacturing (AM) parts.

“Siemens Energy’s extensive expertise in functional AM printing applications, combined with Ansys’ game-changing AM design technologies, improves how organizations of all sizes cost-efficiently produce highly complex parts,” Quan Lac, Siemens Energy head of additive manufacturing, Americas, said. “Engineering teams’ paramount goal is to print parts right the first time, and this partnership makes training them on that task possible. Together, we will train our joint customers to design and build products faster, ensuring customers receive new innovations with markedly greater speed.”

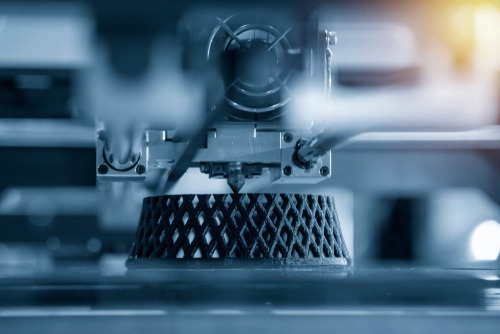

Designers in many industries often lack expertise in AM manufacturing, print preparation, and simulation tools which can result in extended development time. The partners will train engineers to affordably produce highly complex parts that cannot be created by conventional manufacturing.

“Our partnership with Siemens Energy brings new AM capabilities to engineers across industries, delivering dynamic insights that will radically advance the AM industry and increase new product innovation,” Shane Emswiler, Ansys senior vice president, said. “By breaking the constraints of traditional manufacturing, we are training designers to turn their visions into reality and substantially improve productivity.”