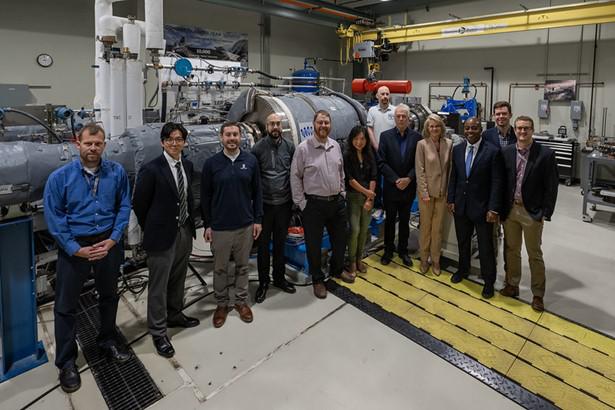

The National Experimental Turbine (NExT) initiative recently demonstrated the one-stage NExT test turbine.

The turbine features cooled vanes and blades. The blades have been used to evaluate advanced manufacturing methods in collaborative efforts among Honeywell, one of the turbine’s manufacturer, Agilis, the turbine’s designer, Penn State, and Hitchiner.

The blades are able to be cast within two months because of printing a cored mold. This method is more accurate than conventional tooling methods required for single-crystal blades and also significantly faster.

Quality checks through scanning quantification indicated that the desired requirements were achieved. Requirements included internal features and aerodynamic shape.

The turbine is a partnership that includes Agilis, Honeywell, Pratt & Whitney, Siemens, and Solar Turbines.

The National Experimental Turbine initiative is located at the Pennsylvania State University Steady Thermal Aero Research Turbine (START) Lab. It is supported by the U.S. Department of Energy and NETL, a U.S. Department of Energy national laboratory that drives innovation and delivers environmentally sustainable technologies.

The START Lab is using the NExT geometry to complete projects funded by the National Aeronautics and Space Administration and the Federal Aviation Administration’s Aviation Sustainability Center, Advanced Research Projects Agency—Energy.

Discussions are underway on how to use NExT’s data.