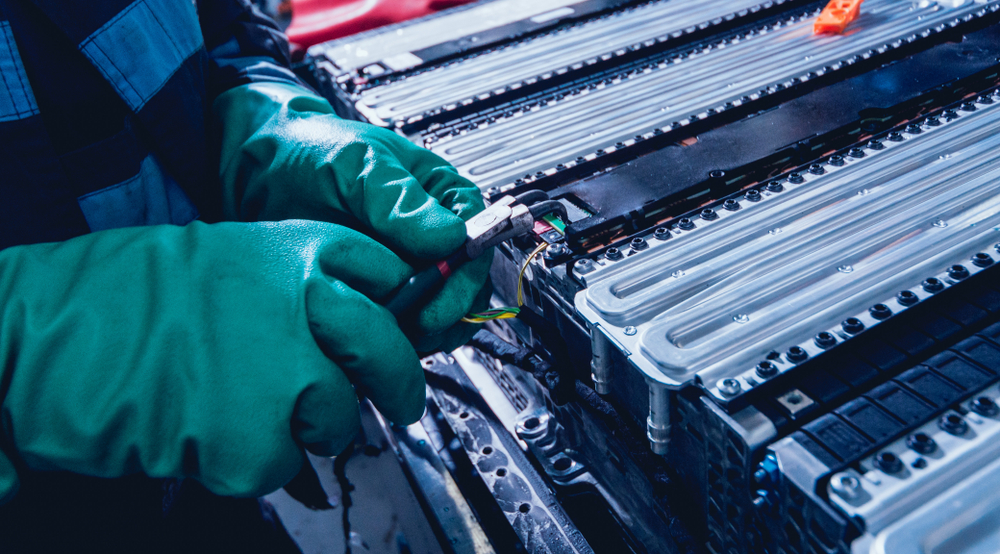

PPG debuted its PPG CORATHERM thermal gap filler during a technical presentation Monday at the Advanced Automotive Battery Conference Europe in Germany.

The coating is designed to help enhance electric-vehicle battery performance, durability, and safety.

Calum Munro, a PPG senior scientist working with automotive original equipment manufacturer coatings, hosted the presentation.

PPG’s booth features several solutions for battery cell and pack applications. One of these solutions is a cathode binder free of the solvent N-Methylpyrrolidone (NMP).

NMP has been labeled as a reproductive hazard by several global regulatory agencies but is widely used in electrode manufacturing.

The display will illustrate how PPG has had success in developing a cost-effective cathode binder that eliminates the use of NMP. The binder helps streamline formulation and application processes by reducing mixing times by up to 90 percent and contributing to longer battery cycle life, PPG said.

PPG’s products include nearly every area of lithium-ion battery design and construction, the company said, which enables its customers to reduce cost per kilowatt hour, increase manufacturing, improve safety, extend service life, and boost energy density.

The conference is one of the largest events for automotive battery technologies worldwide and is expected to attract more than 1,000 participants. The show runs through Thursday.