PPG recently partnered with Cellforce Group, a German company that develops and produces high-performance lithium-ion pouch cells for special automotive applications, to develop sustainable battery cell solutions for the electric vehicle and mobility segment.

PPG will supply the company with cathode binder systems that are N-Methylpyrrolidone (NMP) solvent free. The solvent is used in electrode manufacturing. PPG’s system eliminates the use of NMP in producing the conductive-carbon slurry that forms cathodes for Li-ion batteries.

Several global regulatory agencies have labeled NMP as a reproductive hazard, and the U.S. Environmental Protection Agency has listed it as an unreasonable risk to workers in certain conditions.

“PPG is eager to partner with the Cellforce Group to build the next generation of battery cell technology that will define a new level of sustainability for the electro-mobility segment,” Markus Vogt, PPG general manager of mobility, said. “Additionally, the partnership enables collaboration to provide critical technology development to increase cell performance and safety.”

Cellforce Group is a joint venture between Porsche and CUSTOMCELLS.

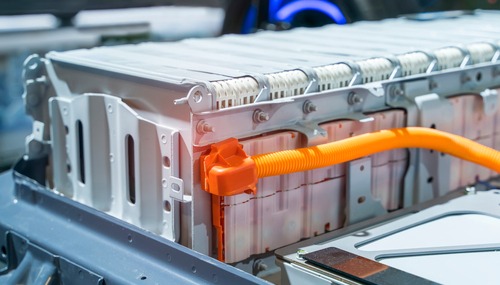

PPG’s materials expertise covers most aspects of Li-ion battery design and construction. The company’s mobility professionals provide solutions for automotive electro-mobility. Solutions include sustainable binder solutions for the battery cell and coating solutions for the battery pack.